Kwilizwe elihlala liguquka lemveliso, ukujika kwamacandelo omatshini e-CNC akhokelela kwinguquko. Ngamashishini afuna ukuchaneka okukhulu, ukusebenza kakuhle, kunye nokwenza ngokwezifiso, itekhnoloji ye-CNC (Ulawulo lwamanani eeKhompyutha) iye yaba yimfuneko, ngakumbi ekuguquleni imisebenzi. Ezi nxalenye zenziwe ngobuchule zinika amandla yonke into ukusuka kwiinjini zeemoto ukuya kwizixhobo ze-aerospace, zenza iinxalenye zomatshini we-CNC zibe lilitye lembombo lenkqubela phambili yoshishino lwangoku.

Kodwa kutheni ezi nxalenye zibaluleke kangaka, kwaye ziyichaza njani imveliso? Makhe siphonononge indlela ukuguqula oomatshini be-CNC kubeka ibhenchmark entsha yokuchaneka, ukusebenza, kunye nokusebenza kakuhle kwemveliso.

Yintoni ukuguqula iCNC Machining Parts?

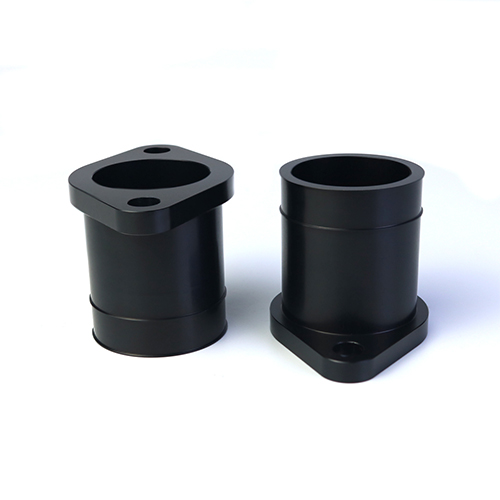

Embindini wayo, ukuguqula oomatshini be-CNC kubandakanya ukususa imathiriyeli kwisixhobo sokusebenza esijikelezayo ukwenza iimilo zecylindrical ezichanekileyo. Le nkqubo iphunyezwa kusetyenziswa iileyile ze-CNC eziphezulu kakhulu, ezicwangciselwe ukuvelisa iinxalenye ngokuchaneka okukhethekileyo kunye nokungaguquguquki.

Imizekelo eqhelekileyo yokuguqula iinxalenye zomatshini ze-CNC ziquka i-shafts, i-bushings, i-spindles, i-screws, kunye ne-flanges, zonke ezifuna ukuchaneka okuphezulu ukuqinisekisa ukusebenza ngokungenamthungo kwizicelo zabo.

Ngokungafaniyo neendlela zokujika zemveli, oomatshini be-CNC banokuvelisa iinxalenye ezinokunyamezelana kwinqanaba le-micron, zibenza zibe zilungele kumashishini apho nokuba ukutenxa kuncinci kunokuphazamisa ukusebenza, okufana ne-aerospace, izixhobo zonyango, iimoto, kunye ne-electronics.

Kutheni ukuguqula iCNC Machining Parts iTshintsho

1. Ukuchaneka okungenakulinganiswa

Ukuchaneka luphawu lokuguqula oomatshini beCNC. Iileyile zale mihla ze-CNC zixhotyiswe ngesoftware ebukhali kunye nezixhobo ezenza ukuba abavelisi bavelise iinxalenye ngokuchaneka okumangalisayo.

Umzekelo, amacandelo e-aerospace afana ne-iturbine shafts okanye izifakelo zonyango ezifana nezikrufu zamathambo zifuna ijometri egqibeleleyo ukuze yenze njengoko bekucetyiwe. Ukuguqulwa kwe-CNC kuqinisekisa ukuba la macandelo ahlangabezana nemigangatho yomgangatho ongqongqo, ukuphelisa umngcipheko ohambelana neempazamo zezandla.

2. Ukwandiswa kokuSebenza kweMveliso

Oomatshini bokujika be-CNC basebenza ngesantya esiphezulu ngelixa begcina ukungaguquguquki kuyo yonke imveliso emikhulu. Ngokungafaniyo neeleyile zezandla, ezifuna ukubekw’ iliso rhoqo komntu, iileyile ze-CNC zinokuziqhuba ngokuzimeleyo, zinciphisa kakhulu ixesha lokuvelisa kunye neendleko zabasebenzi.

Kuba amashishini avelisa imiqulu emikhulu yamacandelo ajikiweyo, afana neemoto okanye oomatshini boshishino, itekhnoloji ye-CNC ivumela ukuveliswa okukhawulezayo, okuneendleko eziphezulu ngaphandle kokuncama umgangatho.

3. Ukwenziwa ngokwezifiso okuphuculweyo

Ukuguquguquka komatshini we-CNC kuvumela abavelisi ukuba bavelise iinxalenye zesiko ezilungiselelwe izicelo ezithile. Ngesoftware yeCAD/CAM ephucukileyo, iinjineli zinokuyila iijiyometri ezintsonkothileyo kwaye ziziguqulele ngokuthe ngqo kwiinkqubo zeCNC.

Nokuba yiprototype enye okanye ibhetshi yamalungu esiko kwiinjini ezisebenza kakhulu, ukujika kwe-CNC kunika inkululeko yoyilo engenakuthelekiswa nanto. Oku kubaluleke kakhulu kumacandelo afana neemoto kunye neempahla zodidi, apho iindawo ezizodwa, ezisebenza kakhulu zifunwa kakhulu.

4. Superior Material Compatibility

Imishini yokuguqula i-CNC inokusingatha uluhlu olubanzi lwezixhobo, ukusuka kwiintsimbi zemveli ezifana ne-aluminium, intsimbi, kunye nobhedu, ukuya kwii-alloys eziphambili kunye neengqungquthela ezifana ne-titanium kunye ne-carbon fiber.

Oku kuguquguquka kwenza abavelisi bahlangabezane neemfuno ezahlukeneyo zamashishini afuna imathiriyeli eneempawu ezithile, njengendawo ekhaphukhaphu ye-aerospace okanye izifakelo zonyango ezinganyangekiyo ku-corrosion.

Izicelo zokuqhuba iiMfuno zokuguqula iiNdawo zoMatshini ze-CNC

1.Ushishino lweemoto

Ukuguqula iindawo zoomatshini be-CNC zibalulekile kwicandelo leemoto, zivelisa izinto ezibalulekileyo ezinje ngeepiston ze-injini, iishafu zegiya, kunye nezinto zokuqhuba. Ukuchaneka kunye nokuqina kwe-CNC-turned parts iqinisekisa ukusebenza kakuhle kwesithuthi, ukusebenza kakuhle kunye nokhuseleko.

2.Ubunjineli beAerospace

Kwi-aerospace, akukho ndawo yempazamo. Amalungu ajikiweyo e-CNC afana neziqhoboshi zenqwelomoya, izixhobo zokumisa inqwelomoya, kunye neeshafti ze-iturbine zenziwa ngokweenkcukacha ezichanekileyo ukuhlangabezana neemfuno eziqatha zokusingqongileyo kokubhabha.

3.Izixhobo zonyango

Ishishini lezonyango lithembele kakhulu kumatshini we-CNC wokuvelisa izixhobo zotyando, ukufakelwa, kunye neprosthetics. Ukuguqula i-CNC machining iqinisekisa ukuba la macandelo awachanekanga kuphela kodwa anokuhambelana ne-biocompatible kwaye akhuselekile ukusetyenziswa kwizicelo ezinobuthathaka.

4.Ezombane

Ukusuka kwiziqhagamshelo ezincinci ukuya kwizitsini zobushushu, ukujika kwe-CNC kudlala indima ebalulekileyo kushishino lombane. Ukukwazi ukusebenza ngezinto ezicekethekileyo kunye nokuvelisa iinxalenye ezincinci, ezintsonkothileyo zenze ukuba i-CNC ijike ibaluleke kakhulu kulo mmandla.

Ukuqhubela phambili kweTekhnoloji kwi-CNC Turning

Intsimi ye-CNC yokujika iyavela ngokukhawuleza, kunye nezinto ezintsha eziphucula isantya, ukuchaneka, kunye nokusebenza:

1. IiLathes ze-CNC ze-Multi-Axis

Iileyile zale mihla ze-CNC ngoku zinezakhono ezininzi ze-axis, zenza ukuba iijiyometri ezintsonkothileyo ziveliswe ngendlela enye. Oku kuphelisa imfuno yemisebenzi yesibini, ukunciphisa ixesha lokuvelisa kunye neendleko.

2. Ukudityaniswa kwe-IoT

Oomatshini be-Smart CNC abaxhotyiswe ngee-sensor ze-IoT bavumela ukubeka iliso kwangexesha lokwenyani kwimisebenzi yomatshini, ukuqinisekisa ulawulo lomgangatho kunye nokugcinwa kwangaphambili.

3. Advanced Cutting Tools

Ukuphuhliswa kwezixhobo zokusika eziphezulu, ezifana ne-diamond-tipped okanye i-coated carbide inserts, iphucule ukusebenza komatshini kunye nokwandisa ubomi besixhobo, nangona usebenza ngezinto ezinzima ezifana ne-titanium okanye i-Inconel.

Ikamva lokuguqula iCNC Machining Parts

Njengoko amashishini eqhubeka efuna ukuchaneka okuphezulu kunye nokusebenza kakuhle, ukuguqula oomatshini be-CNC kuya kudlala indima ebaluleke kakhulu. Ukudityaniswa kobukrelekrele bokwenziwa kunye ne-automation ilungele ukwenza oomatshini bokuguqula i-CNC babe krelekrele ngakumbi kwaye banakho, okuvumela ukwenziwa ngokwezifiso okukhulu kunye nemijikelezo yokuvelisa ngokukhawuleza.

Ngaphaya koko, ngokutyhalela ekuzinzeni, umatshini we-CNC wamkela iindlela ezisebenzisekayo eco-friendly, ezinjengokunciphisa inkunkuma yezinto ngokusebenzisa iinkqubo zoomatshini eziphuculweyo kunye nokusetyenziswa kwezinto ezinokuphinda zisetyenziswe.

Isiphelo: Ukuguqula iCNC Machining Parts njengeCatalyst for Progress

Ukunyuka kwamacandelo omatshini aguqukayo e-CNC kubonisa ukutsibela phambili okubalulekileyo kumashishini okuvelisa. Ngokudibanisa ukuchaneka, ukusebenza kakuhle, kunye nokuguquguquka, ezi nxalenye ziqhuba izinto ezintsha kuluhlu olubanzi lwezicelo, ukusuka kwezothutho kunye nokhathalelo lwempilo ukuya kwitekhnoloji kunye nokhuselo.

Njengoko itekhnoloji ye-CNC iqhubela phambili, amathuba okuguqula iinxalenye zomatshini we-CNC akanamda. Kubavelisi abajonge ukuhlala bekhuphisana kwihlabathi eliguqukayo ngokukhawuleza, ukutyala imali kubuchule bokujika be-CNC ayisiyonto nje inketho-yinto eyimfuneko.

Nokuba kunika amandla izithuthi zesizukulwana esilandelayo, ukunika amandla izixhobo zonyango ezisindisa ubomi, okanye ukwenza izinto zombane zexesha elizayo, ukuguqula iindawo zomatshini we-CNC ziphambili kwimveliso echanekileyo kwinkulungwane yama-21.

Ixesha lokuposa: Jan-06-2025