PFT, Shenzhen

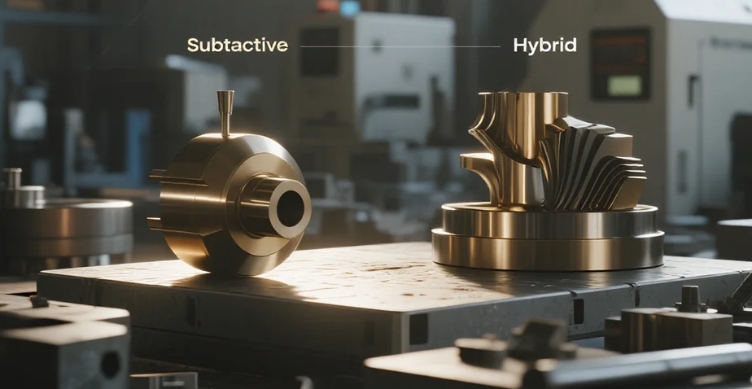

Olu pho nonongo luthelekisa ukusebenza komatshini we-CNC wokuthotywa kwemveli kunye ne-hybride ekhulayo ye-CNC-Additive Manufacturing (AM) yokulungiswa kwezixhobo zoshishino. Iimethrikhi zokusebenza (ixesha lokulungisa, ukusetyenziswa kwezinto eziphathekayo, amandla omatshini) zilinganiswe ngokusebenzisa iimvavanyo ezilawulwayo kwi-stamping eyonakeleyo iyafa. Iziphumo zibonisa iindlela ezixubileyo zinciphisa inkunkuma yezinto eziphathekayo ngama-28-42% kwaye zifinyeze imijikelo yokulungisa nge-15-30% ngokubhekiselele kwiindlela zokunciphisa kuphela. Uhlalutyo lwe-Microstructural luqinisekisa amandla okuqina okuthelekiswayo (≥98% yesixhobo sokuqala) kumacandelo okulungiswa kwe-hybrid. Umda ophambili ubandakanya imiqobo yejometri entsonkothileyo yokubekwa kwe-AM. Ezi ziphumo zibonisa i-hybrid CNC-AM njengesicwangciso esisebenzayo sokugcinwa kwesixhobo esizinzileyo.

1. Intshayelelo

Ukuthotywa kwezixhobo kubiza amashishini okuvelisa i-240B ngonyaka (NIST, 2024). Ukulungiswa kwe-CNC yemveli yokunciphisa kususa amacandelo awonakalisiweyo ngokusila / ukugaya, ngokuphindaphindiweyo ukulahla> i-60% yezinto ezinokulondolozwa. Ukudityaniswa kwe-Hybrid CNC-AM (i-eneji ethe ngqo kwisixhobo esikhoyo) ithembisa ukusebenza kakuhle kwezixhobo kodwa ayinakuqinisekiswa kwemizi-mveliso. Olu phando lubalula iingenelo zokusebenza zokuqukuqela komsebenzi oxutyiweyo ngokuchasene neendlela eziqhelekileyo zokuthotywa kwexabiso eliphezulu lokulungiswa kwezixhobo.

2 Ulwazi-nkqubo

2.1 Uyilo loMfuniselo

Iintlanu ezonakalisiweyo ze-H13 zentsimbi ziyafa (ubukhulu: 300 × 150 × 80mm) zenze iindlela ezimbini zokulungisa:

-

Iqela A (Elokukhuphayo):

- Ukususwa komonakalo nge-5-axis milling (DMG MORI DMU 80)

-I-Welding filler deposition (GTAW)

-Gqibezela umatshini ukuya kwiCAD yokuqala -

Iqela B (Hybrid):

-Ukususwa kwesiphene esincinci (<1mm ubunzulu)

- Ukulungisa i-DED usebenzisa i-Meltio M450 (316L ucingo)

-I-Adaptive CNC remachining (Siemens NX CAM)

2.2 Ukufunyanwa kweDatha

-

Ubuchule bokuSebenza: imilinganiselo yobunzima kwangaphambili/ngemva kokulungiswa (Mettler XS205)

-

Ukulandelela ixesha: Ukujongwa kwenkqubo nge-IoT sensors (ToolConnect)

-

Uvavanyo loomatshini:

-Ukuqina kwemephu (Buehler IndentaMet 1100)

- Iisampulu ze-tensile (ASTM E8/E8M) ezivela kwiindawo ezilungisiweyo

Iziphumo ezi-3 kunye nohlalutyo

3.1 Ukusetyenziswa kweZibonelelo

Itheyibhile 1: Uthelekiso lweeMetrikhi zeNkqubo yokuLungisa

| Metric | Ukulungiswa kokuthabatha | Ukulungiswa kweHybrid | Ukunciphisa |

|---|---|---|---|

| Ukusetyenziswa kwezinto | 1,850g ± 120g | 1,080g ± 90g | 41.6% |

| Ixesha lokulungisa elisebenzayo | 14.2 iyure ± 1.1 iyure | 10.1 iyure ± 0.8 iyure | 28.9% |

| Ukusetyenziswa kwamandla | 38.7 kWh ± 2.4 kWh | 29.5 kWh ± 1.9 kWh | 23.8% |

3.2 Imfezeko yoomatshini

Iisampulu ezilungisiweyo zeHybrid zibonisiwe:

-

Ukuqina okungaguqukiyo (52–54 HRC vs. yoqobo 53 HRC)

-

Amandla okugqibela: 1,890 MPa (±25 MPa) - 98.4% yesiseko semathiriyeli

-

Akukho nxunguphalo lwe-interfacial delamination kuvavanyo lokudinwa (10⁶ cycles at 80% isivuno soxinzelelo)

Umzobo 1: I-Microstructure ye-interface yokulungisa i-hybrid (SEM 500 ×)

Qaphela: Ulwakhiwo lweenkozo olulinganayo kumda wokudityaniswa lubonisa ulawulo olusebenzayo lobushushu.

4 Ingxubusho

4.1 Iimpembelelo zokuSebenza

Ukunciphisa ixesha le-28.9% livela ekupheliseni ukususwa kwezinto ezininzi. Ukusetyenzwa kweHybrid kungqina ukuba kunenzuzo:

-

Izixhobo zelifa kunye nesitokhwe semathiriyeli esiyekiweyo

-

Iijometri ezintsonkothileyo eziphezulu (umzekelo, iitshaneli zokupholisa ezisemthethweni)

-

Iimeko zokulungisa umthamo ophantsi

4.2 Imiqobo yobuGcisa

Imida iphawulwe:

-

Ubuninzi be-engile yokubeka: 45° ukusuka kumda othe tye (unqanda iziphene ezingaphaya)

-

Umahluko wobunzima bomaleko we-DED: ±0.12mm ifuna iindlela zesixhobo eziguqukayo

-

I-post-process unyango lwe-HIP luyimfuneko kwizixhobo ze-aerospace-grade

5 Isiphelo

I-Hybrid CNC-AM inciphisa ukusetyenziswa kwezixhobo zokulungisa izixhobo nge-23-42% ngelixa igcina ukulingana komatshini kwiindlela zokukhupha. Ukuphunyezwa kuyacetyiswa kumacandelo anobunzima bejometri apho ugcino lwempahla luthethelela iindleko zokusebenza kwe-AM. Uphando olulandelayo luya kwandisa izicwangciso ze-deposition kwiintsimbi zesixhobo esiqinileyo (> 60 HRC).

Ixesha lokuposa: Aug-04-2025