Kwihlabathi eliphakamileyo lemveliso yamandla kunye noomatshini boshishino, ukuchaneka kunye nokusebenza kakuhle akunakuxoxisana. Ukusetyenziswa kobuchwephesha obutsha kumatshini wokwenza ii-cylinder ze-iturbine kuguqula inkqubo yokwenziwa kwemveliso, ivumela impumelelo ekusebenzeni, ukuqina, kunye nokuzinza. Ukusuka ekudalweni kombane ukuya kwinqwelomoya, ubuchule bomatshini obuphucukileyo buchaza ngokutsha indlela iisilinda zeiturbine eziyilwe, ziveliswe kwaye zigcinwe ngayo.

Ukubaluleka koMatshini we-Turbine Cylinder

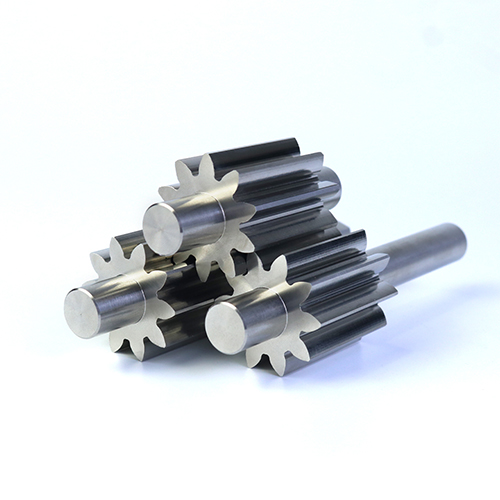

Iisilinda ze-turbine zidlala indima ebalulekileyo kwiinkqubo ezinjengeeinjini zomphunga, iiinjini zegesi, kunye neejenereyitha zombane wamanzi. La malungu kufuneka anyamezele amaqondo obushushu agqithisileyo, uxinzelelo, kunye nesantya sokujikeleza. Ukufezekisa ukuchaneka okufunekayo ngexesha lomatshini kuqinisekisa:

● Ukusebenza Ngokugqibeleleyo:Ukunciphisa ukulahlekelwa kwamandla ngexesha lokusebenza.

●Ukomelezwa koKuhlala ixesha elide:Ukwandisa umjikelo wobomi bamacandelo eijini.

● Ukhuseleko oluphuculweyo:Ukunciphisa imingcipheko ehambelana neendawo ezinoxinzelelo oluphezulu.

Izinto ezintsha ezintsha kwi-Turbine Cylinder Machining

1.High-Precision CNC Machining

YangokuCNC (iKhompyutha yoLawulo lwamanani) oomatshinibamisela imigangatho emitsha yokuchaneka kwimveliso ye-cylinder ye-injini. Aba matshini bavumela:

●Ukuchaneka kweNqanaba leMicrometer:Ukuhlangabezana nokunyamezela okungqongqo okufunekayo ekusebenzeni kakuhle kweinjini yomoya.

●Iijometri eziNxanxayo:Ukuvumela ukuveliswa koyilo oluntsonkothileyo olukhulisa ukuhamba komoya kunye nokuhanjiswa kobushushu.

● Inkunkuma eNcitshisiweyo:Ukunciphisa inkcitho yezinto eziphathekayo ngeendlela ezichanekileyo zokusika.

1.Udibaniso lweMveliso eyoNgezelelweyo

Imveliso eyongezelelweyo, okanye ushicilelo lwe-3D, luba lutshintsho lomdlalo kwi-turbine cylinder prototyping kunye nokulungiswa:

●Ukuchwetheza ngokuKhawuleza:Ikhawulezisa uphuhliso loyilo lwe turbine entsha.

● UPhuculo lweMathiriyeli:Ivumela amalungu alula kodwa ahlala ixesha elide.

● Ulungiso lwasekuhlaleni:Yenza ukubuyiswa okuchanekileyo kweendawo ezigugileyo okanye ezonakalisiweyo, ukwandisa ubomi be-cylinder.

1.I-Laser kunye ne-Waterjet Cutting

Ubuchwephesha bokusika obukwinqanaba eliphezulu njenge-laser kunye neenkqubo zejet zamanzi ziguqula ukumila kweesilinda ze-iturbine:

●Non-Contact Cutting:Ukunciphisa umngcipheko wokulimala kwe-thermal.

● Ukusebenziseka ngeendlela ezahlukeneyo:Iphatha uluhlu olubanzi lwemathiriyeli, kubandakanywa ii-superalloys eziqhelekileyo ezisetyenziswa kwiiinjini zomoya.

●ImiSebenzi enesantya esiphezulu:Inciphisa amaxesha emveliso ngelixa igcina umgangatho.

1.I-Automation yeRobhothi

Iinkqubo zerobhothi zongeza ukungaguquguquki kunye nokusebenza kakuhle kumatshini we-cylinder ye-turbine:

●Utshintsho lweSixhobo oluzenzekelayo:Inciphisa ixesha lokuphumla phakathi kweenkqubo zomatshini.

● Ukuphatha ngokuchanekileyo:Iqinisekisa umgangatho ongaguqukiyo kuyo yonke imveliso eqhutywayo enkulu.

● Uhlolo oluqhutywa yi-AI:Uchonga iziphene ngexesha lokwenyani ukuze ulungiswe kwangoko.

IiNzuzo zobuChwephesha obuNtsha kuMatshini weTurbine

● Imijikelo yeMveliso eKhawulezayo:Izinto ezintsha ezifana ne-CNC automation kunye neenkqubo zerobhothi zinciphisa kakhulu ixesha lomatshini.

●Ucikizeko lweendleko:Iinkqubo eziphuculweyo zehlisa iindleko zemveliso ngaphandle kokubeka esichengeni umgangatho.

●Uzinzo:Inkunkuma yezinto ezincitshisiweyo kunye noomatshini abasebenzisa amandla abonge amandla baxhasa iinjongo zokusingqongileyo.

●Ukusebenza okongeziweyo:Ukuchaneka komatshini kubangela iisilinda ze-iturbine eziphakamisa ukusebenza kakuhle kunye nokuthembeka.

Izicelo kuwo wonke amaShishini

● IsiZukulwana saMandla:Iisilinda ze-iturbine zintliziyo yomphunga kunye neeinjini zegesi, ezibalulekileyo kwimveliso yombane. Ubuchwephesha obutsha buqinisekisa ukusebenza okungaguqukiyo, nakuseto lwamandla ahlaziyekayo njengezityalo ze-geothermal.

● Isiphekepheke:Iinjini zeenqwelomoya zithembele kumalungu einjini yomoya ukuze zimelane neemeko ezinzima. Ubuchwephesha obuphezulu buvumela ukuveliswa kwezinto ezilula, ezinamandla aphezulu.

● I-Oli neGesi:Iiiturbines ezisetyenziswa kude nonxweme kunye nokwemba elunxwemeni zixhamla kwiisilinda ezomeleleyo ezenziwe ngoomatshini ukunyamezela imekobume erhabaxa.

Oko Likuphanjelwe Ikamva

Ikamva lomatshini we-turbine cylinder machining lilele ekudityanisweni ngakumbi kokwenziwa kwe-smart, apho oomatshini be-AI kunye ne-IoT-enabled baya kuqhuba imisebenzi yokuzimela. Izisombululo zeHybrid ezidibanisa ukuveliswa kunye nemveliso yokongeza ziya kunika ukuguquguquka okungenakulinganiswa, ngelixa izenzo ezizinzileyo ziya kuhlala ziphambili.

Ukuqukumbela

Ukusetyenziswa kobuchwepheshe obutsha kumatshini wokwenza iisilinda zeinjini kubonisa ixesha elibalulekileyo kumashishini axhomekeke kwiiinjini zomoya. Ngokwamkela ubuchule bokusika, abavelisi bafikelela kwinqanaba elingazange libonwe ngaphambili lokuchaneka, ukusebenza kakuhle kunye nokuzinza.

Njengoko amandla kunye nembonakalo yomhlaba yemizi-mveliso iqhubeka nokuvela, ukusungulwa komatshini we-iturbine cylinder kuya kudlala indima ebalulekileyo ekunikeni amandla inkqubela phambili, ukusuka kumandla ahlaziyekayo ukuya kwiinjini zenqwelomoya zesizukulwana esilandelayo. Amashishini amkela ezi nkqubela phambili aya kukhokela indlela yokubumba ikamva apho ukuchaneka kuhlangabezana nokusebenza.

Ixesha lokuposa: Dec-16-2024