iMagnetic vs Pneumatic Workholding ye-Thin Sheet yeAluminiyam

Umbhali: PFT, Shenzhen

Abstract

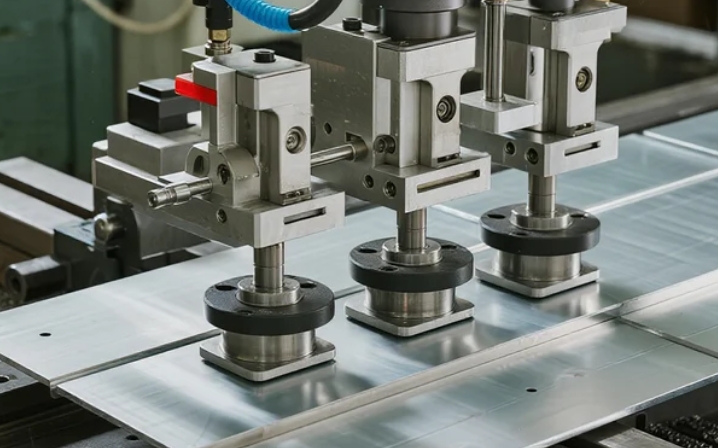

Ukuchaneka kwe-aluminiyam yamaphepha amancinci (<3mm) ijongene nemingeni ebalulekileyo yokusebenza. Olu phononongo luthelekisa iinkqubo ezibambekayo zemagneti kunye ne-pneumatic phantsi kweemeko zokugaya ze-CNC ezilawulwayo. Iiparamitha zovavanyo ziquka ukungaguquguquki kwamandla okubamba, ukuzinza kwe-thermal (20°C–80°C), ukudambisa ivibration, kunye nokugqwetheka komphezulu. Iichucks ze-vacuum ze-pneumatic zigcine i-0.02mm flatness kwi-0.8mm sheets kodwa ifuna umphezulu wokutywina ongaguqukiyo. Iichucks ze-Electromagnetic zenza ukufikelela kwi-5-axis kunye nexesha elincitshisiweyo lokuseta ngama-60%, kodwa imisinga ye-eddy eyenziwe yabangela ukufudumeza kwendawo okungaphezulu kwe-45 ° C kwi-15,000 RPM. Iziphumo zibonisa iisistim zokufunxa zilungiselela ukugqitywa komphezulu wamaphepha >0.5mm, ngelixa izisombululo zemagnethi ziphucula ukuguquguquka kokwenziwa kweprototyping ekhawulezayo. Unyino lubandakanya iindlela ezingavavanywanga zemixube kunye nezinye izinto ezincamathelayo.

1. Intshayelelo

Amaphepha e-aluminiyam amancinci amashishini anamandla ukusuka kwi-aerospace (izikhumba ze-fuselage) ukuya kwi-electronics (ukwenziwa kwe-heat sink). Nangona kunjalo uphando lweshishini luka-2025 lutyhila i-42% yeziphene ezichanekileyo zisuka kwintshukumo yomsebenzi ngexesha lomatshini. Izibambisi zoomatshini eziqhelekileyo zihlala zigqwetha amaphepha angaphantsi kwe-1mm, ngelixa iindlela ezisekwe kwiteyiphu zingenako ukuqina. Olu phononongo lubalula izisombululo ezibini eziphambili: iichucks ze-electromagnetic leveraging control remanence systems kunye ne-pneumatic systems ezinolawulo lwe-vacuum ye-multi-zone.

2 Ulwazi-nkqubo

2.1 Uyilo loMfuniselo

-

Izinto: 6061-T6 aluminium sheets (0.5mm/0.8mm/1.2mm)

-

Izixhobo:

-

Imagnethi: GROB 4-axis electromagnetic chuck (0.8T ukuqina ebaleni)

-

Umoya: Ipleyiti yevacuum ye-SCHUNK ene-36-zone manifold

-

-

Uvavanyo: Ukunyuka komphezulu (i-laser interferometer), ukucinga nge-thermal (FLIR T540), uhlalutyo lokungcangcazela (i-3-axis accelerometers)

2.2 IiProthokholi zovavanyo

-

Uzinzo oluzinzileyo: Ukulinganisa ukuphambuka phantsi kwe-5N yamandla asecaleni

-

Ukuhamba ngeBhayisikile ngeThermal: Rekhoda iqondo lobushushu ngexesha lokugaya (Ø6mm end Mill, 12,000 RPM)

-

Ubungqongqo obuDynamic: Ukulinganisa i-vibration amplitude kwiifrikhwensi ezivakalayo (500–3000 Hz)

Iziphumo ezi-3 kunye noHlahlelo

3.1 UkuQhwatha koMsebenzi

| Ipharamitha | I-Pneumatic (0.8mm) | Imagnethi (0.8mm) |

|---|---|---|

| Avg. Uphazanyiso | 0.02mm | 0.15mm |

| Ixesha lokumisela | 8.5 imiz | 3.2 imiz |

| Ukunyuka kweTemp enkulu | 22°C | 48°C |

Umzobo 1: Iinkqubo zokufunxa zigcinwe <5μm ukuguquguquka komphezulu ngexesha lokusila ubuso, ngelixa i-magnetic clamping ibonise i-0.12mm edge lift ngenxa yokwandiswa kwe-thermal.

3.2 Iimpawu zeVibration

I-pneumatic chucks inciphisa i-harmonics nge-15dB kwi-2,200Hz - ibaluleke kakhulu kwimisebenzi yokugqiba kakuhle. Ukubamba ngemagnethi kubonise i-40% yokuphakama okuphezulu kumaza okudibana kwezixhobo.

4 Ingxubusho

4.1 URhwebelwano lweTekhnoloji

-

I-Pneumatic Advantage: Uzinzo oluphezulu lwe-thermal kunye ne-vibration damping suit suit high-tolerance applications ezifana neziseko ze-optical component.

-

Umda weMagnetic: Uhlengahlengiso oluKhawulezayo luxhasa iindawo zevenkile yemisebenzi ephethe iibhetshi ezahlukeneyo.

Isithintelo: Uvavanyo aluqukwanga amaphepha anemingxuma okanye aneoyile apho ufumfulo lwehla nge-70%. Izisombululo zeHybrid zifuna ufundo lwexesha elizayo.

5 Isiphelo

Kumatshini ocekethekileyo we-aluminium sheet:

-

Ukusebenza kwe-pneumatic kuzisa ukuchaneka okuphezulu kobunzima> 0.5mm kunye nomgangatho ongenakuchaphazeleka

-

Iisistim zemagneti zinciphisa ixesha elinganqunyulwanga ngama-60% kodwa zifuna iindlela zokupholisa kulawulo lobushushu

-

Ukhetho olulolona luxhomekeke kwiimfuno zokuphumelela xa kuthelekiswa neemfuno zokunyamezelana

Uphando lwexesha elizayo kufuneka luphonononge i-adaptive hybrid clamps kunye nokuyila kokuphazamiseka kwe-electromagnetic.

Ixesha lokuposa: Jul-24-2025