Namhlanje's ekhawulezayoimveliso kwihlabathi, amashishini kuwo onke amashishini ahlukeneyo axhomekeke ngakumbi kumatshini wokwenza isiko ukuhlangabezana nemfuno enyukayo yezixhobo zobunjineli obuchanekileyo. Njengoko amashishini aguqukayo kunye noyilo lwemveliso lusiba nzima ngakumbi, ukukwazi ukuvelisa iinxalenye zesiqhelo kunye neenkcukacha ezichanekileyo akuzange kubaluleke ngakumbi. Ukucwangciswa komatshini kunika isisombululo esiguquguqukayo, esineendleko, kunye nesisebenzayo kwiinkampani ezifuna umgangatho ophezulu, amacandelo enziwe ngokufanelekileyo ahambelana neemfuno zabo ezizodwa.

Ukusuka kwi-aerospace ukuya kwizixhobo zonyango, iimoto ukuya kwi-electronics, imfuno yeendawo ezenziwe ngoomatshini iyanda. Eli nqaku liphonononga ukuba yintoni na isiko lomatshini, kutheni lifumana ukuthambekela kuwo onke amashishini, izibonelelo elizinikezelayo, kwaye liyiguqula njani imbonakalo yomhlaba.

Yintoni Custom Machining?

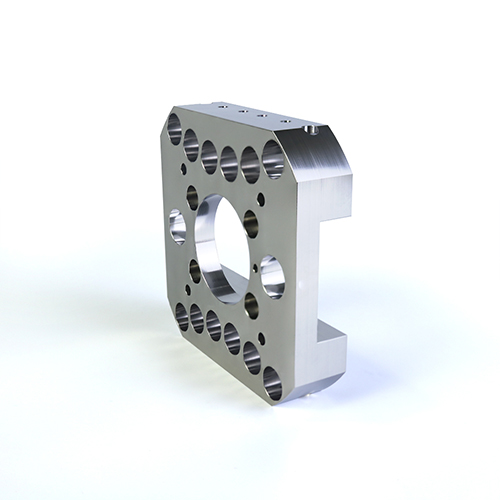

Custom Machining ibhekisa kwinkqubo yokwenziwa apho i-workpiece (ehlala yenziwe ngentsimbi, iplastiki, okanye imathiriyeli edibeneyo) ibunjwe, isikwe, okanye igqitywe ukuhlangabezana nemilinganiselo ethile kunye nokunyamezelana. Ngokungafaniyo nemveli, izinto eziveliswe ngobuninzi, ukwenziwa komatshini kulungiselelwe iimfuno ezichanekileyo zomthengi, zivumela iijometri ezintsonkothileyo, ukunyamezelana okuqinileyo, kunye nokugqitywa komgangatho ophezulu.

Ukusebenzisa itekhnoloji ezifanaCNC(IComputer Numerical Control) ukwenza machining, ukuguba, ukujika, ukucola, kunye nokugrumba, ukwenziwa komatshini ngokwesikovelisa iindawoyezinto eziyinkimbinkimbi-ukusuka kwizinto ezilula, ezisebenzayo ukuya kwizinto eziyinkimbinkimbi, ezichanekileyo eziphezulu kumashishini afana ne-aerospace, i-automotive, unyango, kunye nokunye.

Kutheni uMatshini wesiNtu ufumana udumo

Izinto ezininzi ziqhube ukuthembela okukhulayo kumatshini wesiko kuwo onke amashishini. Ezi ziquka:

●Ukonyusa Ukuntsonkotha kuYilo:Njengoko amashishini etyhala imida yokuqalisa izinto ezintsha, uyilo lwemveliso luya lusiba nzima ngakumbi. Ukucwangciswa ngokwesiko kuvumela abavelisi ukuba benze iinxalenye ezihlangabezana neenkcukacha ezintsonkothileyo, zibonelela ngokuguquguquka ukuvelisa iinxalenye ezinemilo entsonkothileyo, iigophe, kunye neempawu ezineenkcukacha eziya kuba nzima okanye zingenzeki ukufikelela ngeendlela zemveli zokuvelisa ubunzima.

● Ukusetyenziswa kwezinto ezahlukeneyo:Ukucwangciswa okwenziwe ngokwesiko kufanelekileyo kwizinto ezininzi ezahlukeneyo, ukusuka kwisinyithi (njenge-aluminium, insimbi engenasici, kunye ne-titanium) ukuya kwiiplastiki (ezifana ne-polycarbonate kunye ne-nylon) kunye ne-composites. Oku kuguquguquka kuvumela abavelisi ukuba bakhethe eyona mathiriyeli ilungileyo kwisicelo sabo esithile, nokuba bafuna izinto ezikhaphukhaphu, zomelele, okanye ezikwaziyo ukuginya.

● Ukuchaneka okuPhezulu kunye noNyamezelo:Enye yeenzuzo eziphambili zokwenziwa komatshini kukukwazi ukufezekisa ukunyamezelana okuqinileyo (ngokuchaneka njenge ± 0.001 intshi okanye ngaphantsi). Kumashishini afana nezixhobo zonyango, i-aerospace, kunye ne-elektroniki, ukuchaneka kubalulekile. Ukucwangciswa ngokwesiko kuqinisekisa ukuba yonke indawo ingena ngokugqibeleleyo kwaye isebenza ngokuthembekileyo, nakwizicelo ezibalulekileyo zobuthunywa.

● IMveliso yoMqulu oPhantsi enexabiso eliphantsi:Ngelixa iindlela zokwenziwa komthamo ophezulu ezifana nokubumba inaliti okanye ukuphosa ukufa kuhlala kufuna izixhobo ezibiza imali eninzi kunye nokungunda, umatshini wokwenza isiko unokubiza ixabiso eliphantsi ukuya kweliphakathi. Kuba ayifuni ukwenziwa kwezixhobo ezikhethekileyo, iindleko ezinxulumene nomatshini wokwenza isiko zihlala ziphantsi, ngakumbi kwiprototyping okanye imveliso encinci yebhetshi.

● Ukuchwetheza okuKhawulezayo kunye nokuphindaphinda:Umatshini wokwenza isiko sisisombululo esifanelekileyo kwiprototyping ekhawulezayo. Iinjineli zinokuvelisa ngokukhawuleza iprototype, ziyivavanye, kwaye ziphindaphinde kuyilo ngaphandle kokulibaziseka okukhulu okanye iindleko. Oku kukhawuleza kukhawulezisa inkqubo yophuhliso kunye nokunciphisa ixesha lokuya kwintengiso yeemveliso ezintsha.

Isebenza Njani iCustom Machining?

Inkqubo yokwenza isiko ibandakanya amanyathelo aphambili aliqela, ngalinye lijolise ekuqinisekiseni ukuba inxalenye yokugqibela ihlangabezana nemigaqo ebekiweyo ngumthengi:

● Inqanaba loYilo:Inyathelo lokuqala kumatshini wokwenza isiko kukwenza uyilo oluchanekileyo. Oku kuqhele ukwenziwa kusetyenziswa isoftware yeCAD (Computer-Aided Design), evumela iinjineli kunye nabaqulunqi ukuba benze imodeli ye-2D okanye ye-3D yenxalenye. Uyilo lweCAD luthi ke luguqulwe lube yikhowudi efundeka ngomatshini, ngokwesiqhelo ngohlobo lwekhowudi ye-G.

● Ukukhethwa kwezinto:Ngokusekelwe kumsebenzi wenxalenye kunye neemfuno ezithile zeprojekthi, izinto ezifanelekileyo zikhethwa. Izinto eziqhelekileyo ziquka iintsimbi ezifana nentsimbi, i-aluminium, i-titanium, kunye nobhedu, kunye neeplastiki zobunjineli ezifana neDelrin, iNylon, kunye ne-PTFE. Izinto eziphathekayo ezineempawu ezithile ezifana nokuchasana nokushisa, i-conductivity, okanye ukuxhatshazwa kwe-corrosion zikhethwa ngokusekelwe kwisicelo esijoliswe kuyo.

● Inkqubo yoMatshini:Ukusebenzisa umatshini we-CNC, izinto eziphathekayo zisikwa ngokuchanekileyo, zenziwe, kwaye zigqityiwe. Umatshini we-CNC ulandela imiyalelo yekhowudi ye-G ukwenza imisebenzi eyahlukeneyo, kuquka ukugaya, ukujika, ukugrumba, okanye ukugaya. Umatshini unokuba nee-axes ezininzi zokuhamba (ngokuqhelekileyo i-3, i-4, okanye i-5 axes) ukuvumela ukusika okuyinkimbinkimbi, okubanzi kunye nokubunjwa.

● Emva kokwenziwa komsebenzi:Emva kwenkqubo yomatshini, amanyathelo okugqiba okongeziweyo anokufuneka, njengokutshatyalaliswa (ukususwa kweengqungquthela ezibukhali), ukupholisa, okanye ukugubungela. La manyathelo emva kokulungiswa anceda ukufezekisa umphezulu ofunwayo kunye nokuphucula ukubonakala kwenxalenye kunye nokusebenza.

● Ulawulo Lomgangatho:Ulawulo lomgangatho yinxalenye ebalulekileyo yokwenziwa komatshini wesiko. Amacandelo ayahlolwa ukuqinisekisa ukuba ayahlangabezana neenkcukacha ezifunekayo kunye nokunyamezelana. Oku kunokubandakanya ukuhlolwa okubonakalayo, umlinganiselo we-dimensional usebenzisa izixhobo ezifana ne-CMM (Ukulungelelanisa oomatshini bokulinganisa), kunye nokuvavanya amandla, ukuqina, kunye nezinye iimpawu zokusebenza.

● Ukuhanjiswa:Emva kokuba inxalenye idlula ulawulo lomgangatho, ilungele ukuhanjiswa kumthengi. Ukutshintsha ngokukhawuleza kunye nokuguquguquka komatshini wokwenza isiko kuqinisekisa ukuba abavelisi banokuhlangabezana nemihla ebekiweyo yokuvelisa.

IiNzuzo eziPhambili zokuCwangcisa ngokuSiko

Ukucwangciswa ngokwesiko kunika uluhlu lweenzuzo, okwenza kube lolona khetho lukhethwayo kumashishini ajonge ukuvelisa izinto ezikumgangatho ophezulu, ezichanekileyo zobunjineli.

● Ukuguquguquka kuYilo nakwiMveliso:I-Custom Machining inokusingatha iindidi ezininzi zoyilo kunye nezixhobo, okwenza kube yinkqubo yokuvelisa eguquguqukayo kakhulu. Nokuba ufuna icandelo elilula okanye elintsonkothileyo kakhulu, elinezinto ezininzi, umatshini wokwenza isiko unokuhlangabezana neemfuno zakho.

● Ukuchaneka nokuchaneka:Umatshini we-CNC ubonelela ngokuchaneka okungahambelaniyo, oko kuyenza ilungele usetyenziso apho iqhezu ngalinye lemilimitha libala. Iindawo eziveliswe ngomatshini wokwenza isiko zinokufikelela ekunyamezeleni ziqine njenge ±0.001 intshi, ukuqinisekisa ukuba imveliso yokugqibela ingena ngokugqibeleleyo kwaye isebenza njengoko bekucetyiwe.

● Iindleko eziNgenelisayo kuMbaleko woMqulu ophantsi:Kumashishini afuna iibhetshi ezincinci okanye iinxalenye zesiqhelo, umatshini wokwenza isiko unokuba sisisombululo esineendleko eziphezulu kuneendlela zokuvelisa zemveli. Ukungabikho kweendleko zokuxhobisa kwangaphambili kunye nokukwazi ukulungelelanisa ngokukhawuleza uyilo lotshintsho okanye uhlaziyo kwenza kube sisisombululo esifanelekileyo kwimveliso ephantsi ukuya ephakathi.

● UkuGqiba komphezulu oPhezulu:Umatshini wokwenza isiko unokufezekisa umphezulu ogqwesileyo ogqityiweyo, oyimfuneko kuzo zombini imbonakalo kunye nomsebenzi wamalungu. Amanyathelo okusebenza emva kokupholishwa, ukugquma, kunye ne-anodizing angasetyenziselwa ukomeleza iipropathi zomphezulu wamalungu, ukuqinisekisa ukuba ziyahlangabezana neemfuno zobuhle kunye nokusebenza.

● Uguqulo oluKhawulezayo:Ukukwazi ukuvelisa ngokukhawuleza iiprototypes okanye iinxalenye ezilungele ukuveliswa kwenza ukuba umatshini wesiko ube yindlela yokuya kumashishini afuna ukunciphisa ixesha lokuya kwintengiso. Nje ukuba uyilo lugqityiwe, oomatshini be-CNC banokuqalisa ukuvelisa iinxalenye ngokukhawuleza, banciphise kakhulu umjikelo wophuhliso.

Amashishini aNcedayo kuMatshini wesiNtu

● I-Aerospace:Ukwenziwa komatshini okuqhelekileyo kubalulekile kwimveliso ye-aerospace, apho iindawo kufuneka zihlangabezane nemigangatho engqongqo yokhuseleko kunye nokusebenza. Izinto ze-injini, izibiyeli, iinxalenye zegiya zokumisa, kunye neeblayidi ze-injini ye-injini ziqhele ukwenziwa ngoomatshini ukuze kuhlangatyezwane neemfuno zeshishini le-aerospace.

● Izixhobo zonyango:Kwicandelo lezonyango, umatshini wokwenza isiko usetyenziselwa ukwenza izixhobo ezifana nezixhobo zotyando, ukufakelwa, kunye neprosthetics. Ezi ndawo zifuna ukuchaneka okuphezulu kwaye kufuneka zihlala zihambelana ne-biocompatible okanye zixhathise ukubola kunye nokunxiba.

● Iimoto:Umatshini wokwenza isiko usetyenziselwa ukwenza izinto eziphambili zeemoto ezinje ngeendawo ze-injini, iziqhoboshi, izinto zokunqunyanyiswa, kunye nangaphakathi. Ukutshiza kuvumela ukuchaneka okuphezulu kunye nokuqina, okuyimfuneko kukhuseleko lwesithuthi kunye nokusebenza.

● Ezombane:Ishishini le-elektroniki lixhomekeke kumatshini wokwenza izinto ezinje ngeendawo ezivalelekileyo, izihlanganisi, kunye neesinki zobushushu. Ezi ndawo zibalulekile ekukhuseleni izixhobo zombane ezibuthathaka kunye nokuqinisekisa ukusebenza okuthembekileyo.

● Izixhobo zoShishino:Umatshini oqhelekileyo usetyenziselwa ukwenza iindawo ezinzima zoomatshini kunye nezixhobo zoshishino. Nokuba ivelisa iigiya, iishafti, okanye izinto ezisebenza ngoxinzelelo lwendalo, ukwenziwa komatshini wokwenza isiko kubonelela ngokuchaneka kunye nokuqina okufunekayo kusetyenziso lwemizi-mveliso.

Ikamva loMatshini wesiNtu

Ikamva lomatshini wokwenza isiko liqaqambile, kunye nokuqhubela phambili kwetekhnoloji eqhubekayo ukuqhubela phambili ishishini. Ukuzenzekela, ukudityaniswa kwe-AI, kunye nezinto eziphambili kulindeleke ukuba zidlale indima ebalulekileyo ekuphuculeni ukuchaneka, ukusebenza kakuhle kunye nokuzinza.

● I-AI kunye ne-Automation:Ukudityaniswa kwe-AI kunye nokufunda koomatshini kwiinkqubo zoomatshini be-CNC kulindeleke ukuba kuphuculwe amandla oomatshini ukulungelelanisa kunye nokwandisa ukusebenza ngexesha langempela, ukuphucula ukusebenza kakuhle kunye nokunciphisa ixesha lokuphumla.

● Udibaniso lweMveliso eyoNgezelelweyo:Ukudityaniswa koshicilelo lwe-3D (imveliso eyongeziweyo) kunye nomatshini wokwenza isiko sele uguqula amashishini ngokunikezela nokuguquguquka okukhulu koyilo. Iinkqubo zokuvelisa i-Hybrid ezidibanisa zombini umatshini kunye noshicilelo lwe-3D ziya zixhaphaka.

● Uzinzo:Njengoko uzinzo luba yingqwalasela ephambili kuwo wonke amashishini, ukwenziwa komatshini wokwenza isiko kuya kuqhubeka nokuvela kugxininiso ekunciphiseni inkunkuma yezinto kunye nokusetyenziswa kwezinto ezinokuphinda zisetyenziswe okanye zilungele indalo.

Ixesha lokuposa: Jun-09-2025