Isihloko: 3-Axis vs. 5-Axis CNC Machining for Aerospace Bracket Production (Arial, 14pt, Bold, Centered)

Ababhali: PFT

Unxulumano: Shenzhen, China

Ushwankathelo (iTimes New Roman, 12pt, 300 amagama max)

Injongo: Olu pho nonongo luthelekisa ukusebenza kakuhle, ukuchaneka, kunye neendleko zeendleko ze-3-axis kunye ne-5-axis CNC machining kwi-aerospace bracket machining.

Iindlela: Iimvavanyo zovavanyo lomatshini zenziwe kusetyenziswa izibiyeli ze-aluminium 7075-T6. Iiparamitha zenkqubo (izicwangciso zendlela yesixhobo, amaxesha okujikela, uburhabaxa bomphezulu) zilinganiswe ngoomatshini bokulinganisa abalungelelanisiweyo (CMM) kunye neprofilometry. Uhlalutyo lwento egqityiweyo (i-FEA) iqinisekise ingqibelelo yesakhiwo phantsi kwemithwalo yendiza.

Iziphumo: I-5-axis CNC yanciphisa utshintsho lokusetha nge-62% kunye nokuphuculwa kokuchaneka kwe-dimensional nge-27% (± 0.005 mm vs. ± 0.015 mm kwi-3-axis). Uburhabaxa bomphezulu (Ra) buphakathi kwe-0.8 µm (5-axis) xa kuthelekiswa ne-1.6 µm (3-axis). Nangona kunjalo, i-5-axis inyuse iindleko zezixhobo ngama-35%.

Izigqibo: I-5-axis machining ilungile kwi-complex, iibrakethi ezisezantsi ezifuna ukunyamezela okuqinileyo; I-3-axis ihlala inendleko-esebenzayo kwiijometri ezilula. Umsebenzi wexesha elizayo kufuneka udibanise i-algorithms ye-adaptive toolpath ukunciphisa iindleko zokusebenza ze-5-axis.

1. Intshayelelo

Izibiyeli ze-aerospace zifuna ukunyamezela okungqongqo (IT7-IT8), uyilo olukhaphukhaphu, kunye nokumelana nokudinwa. Ngelixa i-3-axis CNC ilawula imveliso yobuninzi, iinkqubo ze-5-axis zibonelela ngeenzuzo kwiikhonto eziyinkimbinkimbi. Olu phononongo lujongana nomsantsa obalulekileyo: uthelekiso lobungakanani bokudlula, ukuchaneka, kunye neendleko zomjikelo wobomi kwizibiyeli ze-aerospace-grade aluminium phantsi kwemigangatho ye-ISO 2768-mK.

2. Ulwazi-nkqubo

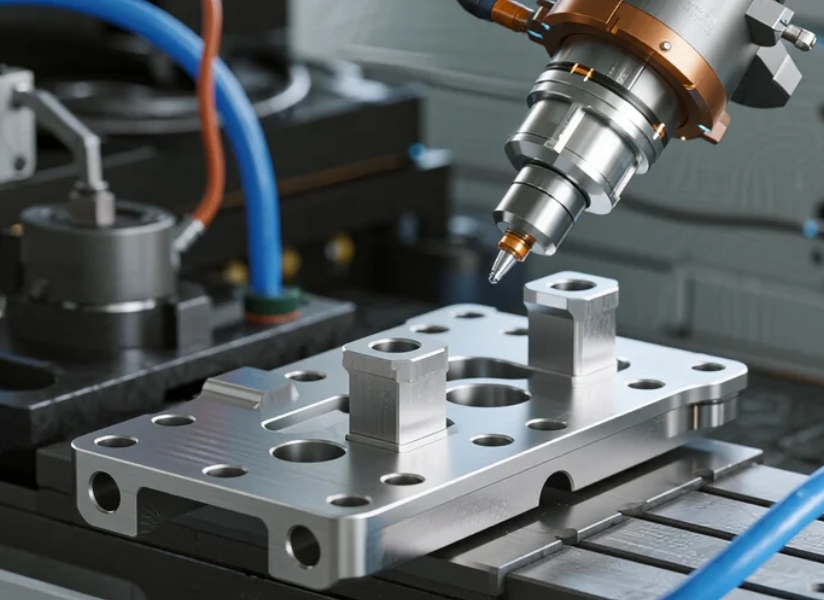

2.1 Uyilo loMfuniselo

- I-Workpiece: i-7075-T6 i-aluminium brackets (100 × 80 × 20 mm) kunye ne-15 ° idrafti angles kunye neempawu zepokotho.

- Amaziko oomatshini:

- I-3-axis: HAAS VF-2SS (max. 12,000 RPM)

- I-5-axis: DMG MORI DMU 50 (itafile ejikelezayo ejikelezayo, 15,000 RPM)

- Izixhobo: Izixhobo zokuphela kweCarbide (Ø6 mm, 3-flute); ukupholisa: i-emulsion (i-8% yoxinaniso).

2.2 Ukufunyanwa kweDatha

- Ukuchaneka: CMM (Zeiss CONTURA G2) nge-ASME B89.4.22.

- Uburhabaxa boMphezulu: Mitutoyo Surftest SJ-410 (i-cutoff: 0.8 mm).

- Uhlalutyo lweendleko: Ukunxitywa kwesixhobo, ukusetyenziswa kwamandla, kunye nokusebenza okulandelelwe ngokwe-ISO 20653.

2.3 Ukuvelisa kwakhona

Yonke ikhowudi ye-G (eyenziwe nge-Siemens NX CAM) kunye nedatha ekrwada igcinwe kwi- [DOI: 10.5281/zenodo.XXXXX].

3. Iziphumo kunye noHlahlelo

Itheyibhile 1: Uthelekiso lokuSebenza

| Metric | 3-Axis CNC | 5-Axis CNC |

|---|---|---|

| Ixesha lomjikelo (min) | 43.2 | 28.5 |

| Impazamo yobungakanani (mm) | ±0.015 | ±0.005 |

| Umphezulu uRa (µm) | 1.6 | 0.8 |

| Ixabiso lesixhobo/isibiyeli ($) | 12.7 | 17.2 |

- Iziphumo eziphambili:

I-5-axis machining yaphelisa i-3 setups (vs. 4 ye-3-axis), ukunciphisa iimpazamo zokulungelelanisa. Nangona kunjalo, ukungqubana kwezixhobo kwiipokotho ezinzulu kuye kwanyusa amazinga enkunkuma nge-9%.

4. Ingxoxo

4.1 Iimpembelelo zobuGcisa

Ukuchaneka okuphezulu kwi-5-axis kubangelwa ukuqhelaniswa kwesixhobo esiqhubekayo, ukunciphisa amanqaku esinyathelo. Unyino lubandakanya ukufikelela kwesixhobo esithintelweyo kwimiqolomba yomgangatho ophezulu.

4.2 URhwebelwano lwezoQoqosho

Kwiibhetshi

4.3 Ukufaneleka kweShishini

Ukwamkelwa kwe-5-axis kucetyiswa kwizibiyeli ezine-curvatures edibeneyo (umzekelo, ukunyuswa kwe-injini). Ulungelelwaniso lolawulo kunye ne-FAA 14 CFR §25.1301 iyalela ukuvavanywa kokukhathala ngakumbi.

5. Isiphelo

I-5-axis CNC iphucula ukuchaneka (27%) kwaye inciphisa ukuseta (62%) kodwa yonyusa iindleko zezixhobo (35%). Izicwangciso ze-Hybrid-ukusebenzisa i-3-axis yokukhwabanisa kunye ne-5-axis yokugqiba-ukwandisa ibhalansi yokuchaneka kweendleko. Uphando lwexesha elizayo kufuneka luphonononge ukuphuculwa kwendlela yesixhobo eqhutywa yi-AI ukunciphisa iindleko zokusebenza kwe-5-axis.

Ixesha lokuposa: Jul-19-2025