Isandla jija imodyuli yomgca wetafile yesilayidi

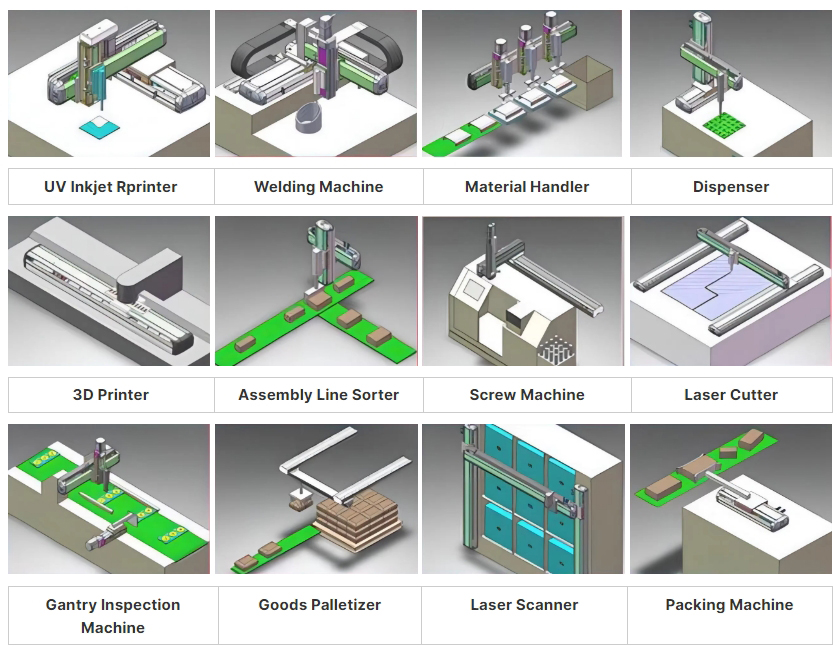

Kwindawo yobunjineli kunye nemveliso, ukuchaneka kunye nokuguquguquka kubaluleke kakhulu. Nokuba ikwidomeyini yerobhothi, i-automation, okanye oomatshini abantsonkothileyo, ukukwazi ukulawula ngokucokisekileyo intshukumo ecaleni kwe-axis yomgama kubalulekile. Apha kulapho iitafile zesilayidi zemodyuli zesandla zingena khona, zibonelela ngesisombululo esiguquguqukayo nesichanekileyo kwiimfuno zolawulo lwentshukumo.

Ukuqonda i-Hand Screw Linear Module yeSlayidi iiTheyibhile

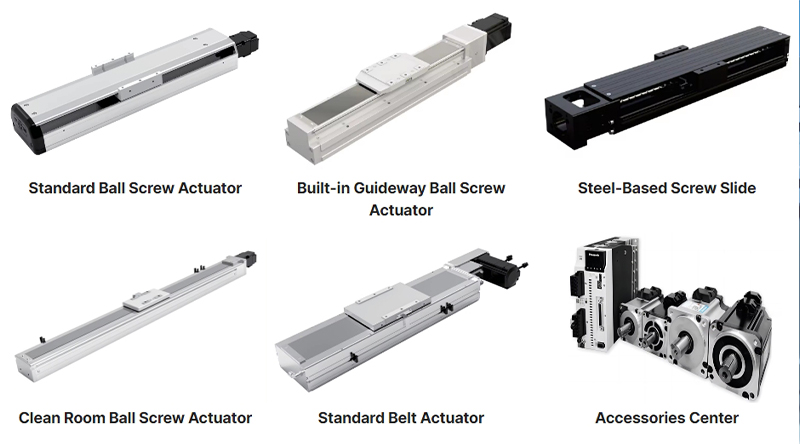

Iitheyibhile zemodyuli yesilayidi ezijijwa ngesandla, ezihlala zibhekiselwa kuzo ngokulula njengeetafile zesilayidi, zizixhobo zoomatshini eziyilelwe ukuququzelela isindululo somgca ecaleni kwendlela ekhokelwayo. Ngokungafaniyo nee actuators zomgca eziqhelekileyo eziqhutywa ziimotor okanye iisistim zepneumatic, iitafile zesilayidi zixhomekeke ekusebenzeni ngesandla ngezikrufu ngesandla. Olu lawulo lwencwadana lubonelela ngeseti eyodwa yeenzuzo kwizicelo ezahlukeneyo.

Ukuchaneka kwiminwe yakho

Enye yeempawu ezibalaseleyo zesandla Screw linear iitafile zesilayidi kukuchaneka kwazo okungaqhelekanga. Ngokusebenzisa izikrufu ezikrwada ngesandla, abaqhubi banolawulo oluthe ngqo kwisantya kunye nendawo yetafile yesilayidi. Eli nqanaba legranular lolawulo lenza ulungelelwaniso oluchanekileyo, luyenze ilungele imisebenzi efuna ukulungiswa kakuhle okanye ukubekwa okucekethekileyo.

Kwiinkqubo zokuvelisa apho ukunyamezela kuqinile kwaye ukuchaneka kubalulekile, iitafile zesilayidi ze-screw zikhanya. Nokuba ikwimigca yokudityaniswa, izixhobo zovavanyo, okanye izikhululo zolawulo lomgangatho, ukukwazi ukubeka ngokuchanekileyo iinxalenye okanye izixhobo kunokuphucula kakhulu imveliso kunye nomgangatho wemveliso.

Ukuguquguquka kwiSicelo

Olunye uncedo oluphambili lwesandla sokujija iitafile zesilayidi zemodyuli kukuguquguquka kwazo. Ngokungafaniyo nee-actuator eziqhutywa ngemoto ezifuna amandla ombane kunye neenkqubo zolawulo ezintsonkothileyo, iitafile zesilayidi zinokudityaniswa ngokulula kwiisetingi ezahlukeneyo ezineemfuno ezincinci zeziseko zophuhliso.

Oku kuguquguquka kwenza iitafile zesilayidi zesandla zilungele uluhlu olubanzi lwezicelo kumashishini ahlukeneyo. Ukusuka kwisixhobo selabhoratri ukuya koomatshini bokwenza amaplanga, ukulula kwabo kunye nokuguquguquka kunika iinjineli kunye nabaqulunqi ukuguquguquka kokuzibandakanya kwiiprojekthi ezahlukeneyo.

Ukwenza lula imisebenzi entsonkothileyo

Ngelixa ii-actuator ezineemoto ezihamba ngemigca zigqwesa kwisantya esiphezulu, kwimisebenzi ephindaphindwayo, iitafile zesilayidi zesandla Screw zibonelela ngeseti eyahlukileyo yezibonelelo. Umsebenzi wabo wezandla uvumela indlela ecacileyo kunye nezandla kwindlela yokulawula ukunyakaza. Oku kunokuba luncedo ngakumbi kwiimeko apho uhlengahlengiso lwexesha lokwenyani lufuneka okanye apho i-automation ingenzeki.

Umzekelo, kuphando kunye nophuhliso kuseto, iinjineli zihlala zifuna ukukwazi ukuphinda-phinda kwiiprototypes okanye ukwenza imifuniselo efuna uhlengahlengiso oluchanekileyo. Iitafile zesilayidi ze-screw slide zibonelela ngeendlela zokwenza olu hlengahlengiso kubhabho, ukuxhobisa abaphandi ukuba bagxile kumsebenzi wabo ngaphandle kokunyanzelwa yimida yeenkqubo ezizenzekelayo.

Isiphelo: Isixhobo sokuChaneka noLawulo

Iitheyibhile zemodyuli yesikrufu somgca wesilayidi zimele ulongezo oluxabisekileyo kwikhithi yezixhobo zeenjineli kunye nabavelisi abafuna ukuchaneka kunye nokuguquguquka kulawulo lwentshukumo. Ngokukwazi kwabo ukuhambisa indawo echanekileyo, ukuguquguquka kwisicelo, kunye nokulula ekusebenzeni, ezi zixhobo zibonelela ngesisombululo esinyanzelisayo kuluhlu olubanzi lwemisebenzi.

Njengoko itekhnoloji iqhubeka nokuvela, kubalulekile ukuba ungahoyi ukusebenza kwezisombululo zoomatshini ezifana neetafile zesikrufu sesilayidi sesandla. Ngelixa i-automation ngokungathandabuzekiyo inendawo yayo, kukho iimeko apho ulawulo lwezandla aluhlali lufanelekile kodwa luyimfuneko. Kwezi meko, iitafile zesilayidi ezijijwa ngesandla zingqina ukuba ngamanye amaxesha, esona sixhobo sisebenzayo seso unokusisebenzisa ngezakho izandla.

Q:Kuthatha ixesha elingakanani ukwenza ngokwezifiso?

A: Ukwenziwa ngokwezifiso kwezikhokelo zomgca kufuna ukumisela ubungakanani kunye neenkcukacha ezisekelwe kwiimfuno, ezithatha malunga neeveki ezi-1-2 zokuvelisa kunye nokuhanjiswa emva kokubeka umyalelo.

Q. Yiyiphi imilinganiselo yobugcisa kunye neemfuno ekufuneka zinikezelwe?

Ar: Sifuna abathengi babonelele ngemilinganiselo emithathu-ntathu yesikhokhelo esifana nobude, ububanzi, kunye nokuphakama, kunye nomthamo womthwalo kunye nezinye iinkcukacha ezifanelekileyo ukuqinisekisa ukulungiswa okuchanekileyo.

Q. Ngaba iisampulu zasimahla zinokubonelelwa?

A: Ngokuqhelekileyo, sinokunika iisampuli ngeendleko zomthengi kwintlawulo yesampuli kunye nemali yokuthumela, eya kubuyiselwa xa ibeka umyalelo kwixesha elizayo.

Umbuzo

A: Ukuba umthengi ufuna ukufakelwa kwendawo kunye nokulungiswa kweempazamo, iintlawulo ezongezelelweyo ziya kusebenza, kwaye amalungiselelo kufuneka axoxwe phakathi komthengi kunye nomthengisi.

Q. Malunga nexabiso

A: Simisela ixabiso ngokweemfuno ezithile kunye neentlawulo zokwenza ngokwezifiso zomyalelo, nceda uqhagamshelane nenkonzo yethu yabathengi ngexabiso elithile emva kokuqinisekisa umyalelo.